Understanding the Role of a Piston Motor Spare Parts Manufacturer

In the landscape of industrial machinery, specifically in the realm of diesel engines, the importance of piston motor spare parts manufacturers cannot be overstated. These manufacturers are pivotal in ensuring that diesel engines operate efficiently and effectively, providing continuous power and reliability. In this article, we will delve into the intricate world of piston motor spare parts, exploring their significance, the manufacturing process, and the role these components play in driving productivity.

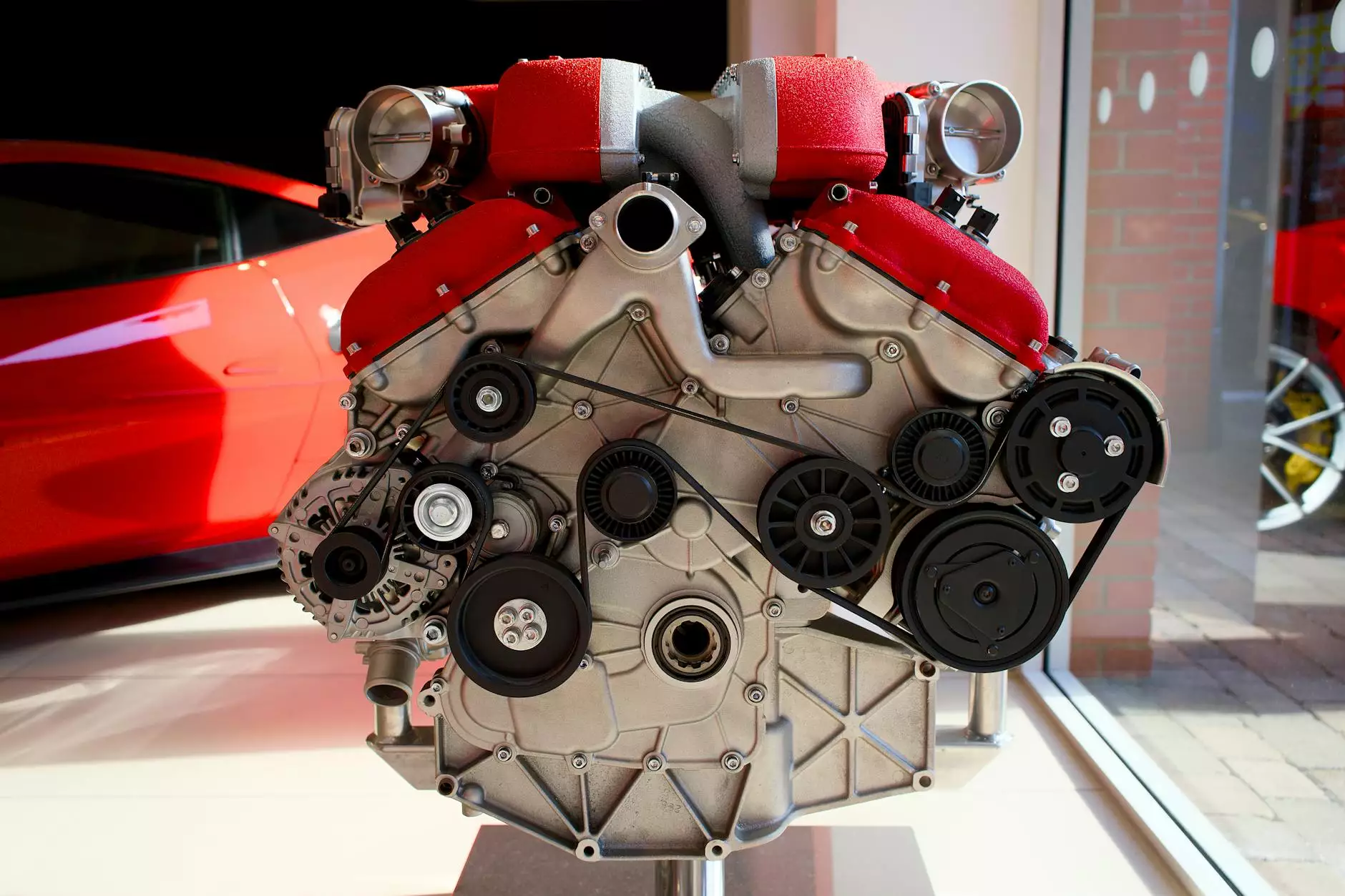

The Diesel Engine: The Heart of Industrial Machinery

Diesel engines are known for their durability and fuel efficiency, making them the backbone of various industries, including agriculture, transportation, and construction. As the demand for reliable diesel engines grows, so does the necessity for quality spare parts, particularly pistons. The piston motor spare parts manufacturer ensures that these critical components meet the rigorous demands of the market.

The Significance of Piston Motors in Diesel Engines

The piston is an integral part of any diesel engine. It moves up and down in the cylinder, compressing the air-fuel mixture and creating the force required to power the engine. This repetitive motion is vital for the overall performance of the engine.

- Power Generation: Pistons convert thermal energy into mechanical work, translating into the engine's power output.

- Efficiency: Well-manufactured pistons can enhance fuel efficiency, reducing operational costs.

- Durability: High-quality pistons contribute to the longevity of diesel engines by resisting wear and tear.

Who is a Piston Motor Spare Parts Manufacturer?

A piston motor spare parts manufacturer specializes in producing components that support the performance and maintenance of diesel engines. These manufacturers take into account various aspects of design, materials, and technology to ensure that their products meet industry standards.

Key Responsibilities of a Piston Motor Spare Parts Manufacturer

Understanding the responsibilities of these manufacturers is essential for anyone involved in the diesel engine industry. Here are some critical responsibilities:

- Research and Development: Innovating and improving piston designs to enhance engine performance.

- Quality Control: Implementing rigorous testing protocols to ensure each component meets safety and durability standards.

- Sourcing Materials: Selecting high-quality materials that withstand the harsh conditions of operation.

- Production Efficiency: Optimizing manufacturing processes to reduce costs without compromising quality.

Components of Piston Motor Spare Parts

Piston motor spare parts encompass a variety of components that work together to ensure efficient functioning. Here are some critical elements:

1. Piston Rings

Piston rings are crucial for sealing the combustion chamber, preventing leakage of gases, and controlling oil consumption.

2. Piston Pins

Piston pins connect the piston to the connecting rod, facilitating motion and energy transfer efficiently.

3. Cylinder Liners

Cylinder liners provide a smooth surface for the piston to move, enhancing durability and efficiency.

4. Gaskets

Gaskets ensure a tight seal between different engine components, preventing oil and coolant leaks.

The Manufacturing Process of Piston Motor Spare Parts

The manufacturing process of piston motor spare parts involves several stages, each critical to producing high-quality components. Here’s a comprehensive overview:

1. Design and Prototyping

The journey begins with meticulous design work, where engineers use computer-aided design (CAD) software to create precise models of the pistons and related components. Prototyping then allows manufacturers to test functionality and durability before mass production.

2. Material Selection

Choosing the right materials is essential. Components must withstand high pressures and temperatures, so manufacturers typically use high-strength steels and special alloys designed for durability and performance.

3. Machining

The machining process involves cutting, shaping, and assembling each part. Advanced machinery ensures precision in dimensions, critical for engine performance.

4. Treatment and Finishing

Components undergo various treatments, such as hardening or coating, to enhance their resistance to wear and fatigue. Finishing processes ensure that all surfaces are smooth and free from impurities.

5. Quality Assurance

A robust quality assurance process involves systematic testing of components for durability, performance, and safety. This step is crucial in minimizing the risk of engine failure.

Piston Motor Spare Parts Suppliers and Their Importance

The role of spare parts suppliers is equally vital in the ecosystem of diesel engine maintenance. They serve a crucial link between manufacturers and end-users, ensuring that the right parts reach mechanics and businesses when needed.

Why Choose Quality Suppliers?

- Reliability: Quality suppliers provide genuine parts that match the specifications of the original equipment manufacturer (OEM).

- Accessibility: With a vast network, they ensure that components are readily available, reducing downtime for operations.

- Technical Support: A good supplier offers technical assistance, helping users select the right components based on their specific needs.

Benefits of Partnering with a Leading Piston Motor Spare Parts Manufacturer

Partnering with a reputable piston motor spare parts manufacturer has several advantages:

1. Increased Efficiency

High-quality parts lead to better engine performance, reducing fuel consumption and increasing productivity.

2. Cost-Effectiveness

Though the initial investment may be higher, using quality parts reduces the likelihood of breakdowns, saving costs in the long run.

3. Enhanced Engine Longevity

Quality pistons and spare parts contribute significantly to the overall lifespan of a diesel engine, ultimately protecting your investment.

Future Trends in Piston Motor Spare Parts Manufacturing

As the industry evolves, several trends are shaping the future of piston motor spare parts manufacturing:

1. Advanced Materials

Emerging materials, such as composites and new alloys, will enhance performance and reduce weight in engine components.

2. 3D Printing Technology

3D printing is revolutionizing the manufacturing process, allowing for rapid prototyping and customizable components.

3. Sustainability Initiatives

Manufacturers are increasingly focusing on sustainable practices, including recycling materials and reducing waste in production.

Conclusion: The Road Ahead for Diesel Engine Performance

In conclusion, the role of a piston motor spare parts manufacturer is central to the functionality and efficiency of diesel engines. By understanding the complexity of piston components, their manufacturing processes, and the benefits of partnering with established suppliers, businesses can ensure that their operations run smoothly and economically. The future of piston manufacturing holds exciting possibilities, with technological advancements promising to further improve the reliability and performance of diesel engines. Embracing these changes will be essential for thriving in an increasingly competitive landscape.

For businesses seeking to enhance their engine performance through high-quality piston components, exploring partnerships with reliable manufacturers such as client-diesel.com can lead to significant advantages and innovations in their operations.